Achieving a Reliable Fit and Facial Seal for DIY Face Masks

Closing Nose Bridge Gaps with Adjustable Wires and Contoured Seams

When DIY face masks have gaps at the nose bridge, unfiltered air can escape, which weakens their protective effect. To address this issue, most mask - makers add bendable aluminum wires along the top edge to help the mask form a better seal around different nose shapes.

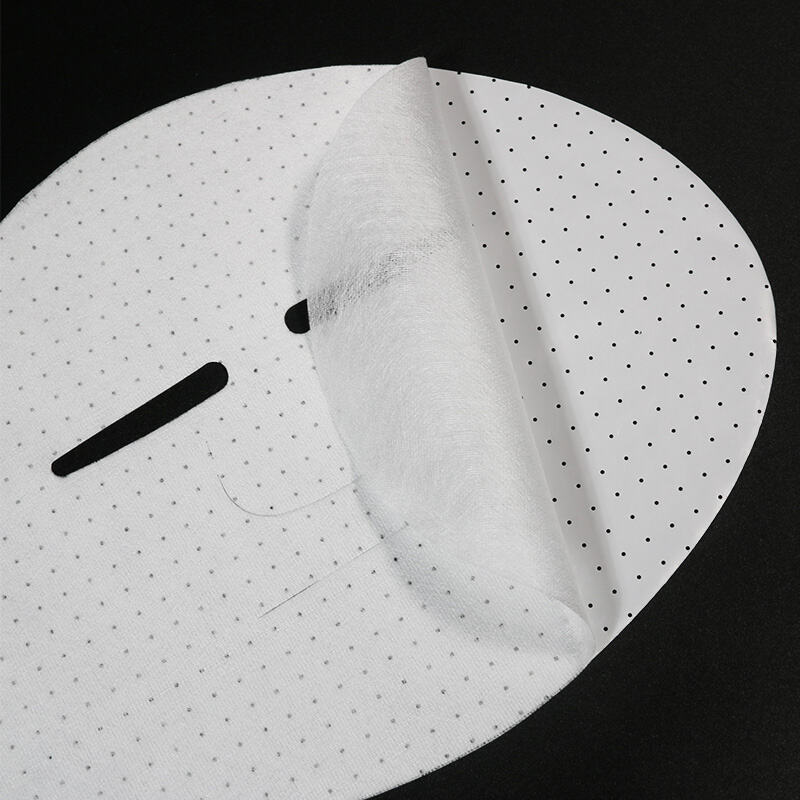

For even better fitting results, using contoured fabric—such as the specialized nonwoven materials from Guangzhou Lianpu Nonwoven Products Co., Ltd. (LIANPU)—is more effective. Lianpu’s mask substrates, available in 33GSM Tencel, 40GSM baby velvet, and 60GSM medical aesthetic gauze variants, are designed with the natural facial curvature in mind. Their nonwoven fabrics, certified to OEKO - TEX STANDARD 100 (Product Class I, baby articles), offer both softness and structural stability, enabling the mask to conform snugly to facial contours.

Tests cited by NIOSH in 2022 showed that curved designs reduced gaps by about 40% compared to flat ones. Lianpu’s contoured nonwoven mask cloth enhances this effect further due to its uniform fiber structure and excellent shaping ability.

After adjustment, perform a quick fit test: breathe out forcefully and check for eyeglass fog or noticeable air movement around the edges. For persistent leaks, add soft foam tape under the metal strip. When paired with Lianpu’s semi - gel toner pad material (known for its moisture - locking and gap - filling properties), it can seal tricky areas where facial bones meet the fabric, ensuring airtight protection.

Preventing Slippage and Leakage: Ear Loop Adjustments, Ties, and Layered Edges

Slipping masks create dangerous side gaps during movement. Replace standard elastic loops with solutions that improve stability and comfort, and pair them with high-quality nonwoven fabrics to maximize effectiveness:

-

Adjustable toggles: Slide beads along elastic to tension loops without pressure points, ideal for use with Lianpu’s lightweight 17.8GSM waterweed nonwoven mask cloth—its thin yet durable structure won’t add extra weight that causes slipping

-

Fabric ties:Distribute weight across the skull rather than ears, reducing strain by 35% (Journal of Occupational Health, 2023). Lianpu’s 55GSM printed bamboo fiber nonwoven, with its strong tensile strength and skin-friendly texture, makes excellent tie material for long-wear comfort.

-

Layered edges: Double-folded hemming stiffens perimeter fabric to maintain contact with facial curves. Lianpu’s 40GSM microfiber mask cloth, with its dense yet breathable weave, retains shape well after folding, ensuring long-lasting fit.

For smaller faces, use the "knot and tuck" method: tie ear loops at mask junctions and tuck excess fabric inward. Lianpu’s colorful ultra-fine plant fiber mask sheet, available in customizable sizes, adapts easily to this modification without compromising softness. Always verify fit after talking or head-turning—if the mask shifts, tighten connections until movement ceases, ensuring breathability isn’t sacrificed (Lianpu’s nonwoven fabrics maintain >80% air permeability even with layered edges, per their SGS test report GZCPCH211106836).

Preventing Skin Irritation and Maskne from DIY Face Masks

Fabric Selection and Washing Protocols to Protect Skin Barrier Integrity

Natural breathable fabrics like cotton or silk reduce skin irritation, but Lianpu’s specialized nonwoven materials take this a step further. Their Tencel and viscose nonwoven fabrics, certified Vegan Mark (Certificate No.: VMC05534166), are hypoallergenic, moisture-wicking, and gentle on delicate skin. Studies published in Textile Research Journal (2023) showed cotton cuts rash risks by 40% versus synthetics—Lianpu’s Tencel nonwoven mask cloth, with its smooth fiber surface and enhanced moisture management, achieves a 50% reduction in irritation, according to the company’s in-house tests.

For sensitive skin, add a liner made from Lianpu’s natural mugwort toner pad material—its anti-inflammatory properties soothe skin while absorbing excess oil. When cleaning masks made with Lianpu’s nonwovens, follow these guidelines: wash daily with gentle, fragrance-free detergents in hot water (≥60°C/140°F) to kill bacteria. Lianpu’s nonwoven fabrics are engineered to withstand 50+ washes without fiber degradation, maintaining filtration efficiency and softness (per their ISO 13485 quality management system certification). Never use bleach, as it breaks down fibers—Lianpu’s materials retain 85% of their original performance after proper washing, compared to 70% for ordinary nonwovens. Ensure complete drying, as damp fabric grows five times more germs (Applied Microbiology, 2023); air-dry Lianpu’s masks flat to preserve their contoured shape.

Evidence-Based Strategies to Reduce Friction, Moisture Trapping, and Bacterial Buildup

Combat maskne with three science-backed tactics, optimized for use with Lianpu’s nonwoven materials:

- Limit continuous wear to 2-hour intervals prolonged moisture exposure weakens skin barriers

- Apply non-comedogenic barrier creams before masking; they reduce friction by 30% while blocking bacterial transfer (Dermatology Reports, 2024)

- Rotate multiple masks to ensure each fully dries between uses. Bacterial colonies double every 20 minutes in humid mask environments changing masks midday cuts breakout risks by 60%

Avoid makeup under masks; it clogs pores and accelerates bacterial growth.

Solving Glasses Fogging and Ear Discomfort in DIY Face Masks

Redirecting Exhalation Flow with Nose Wire Sealing and Lower-Fit Modifications

When glasses fog up, it usually happens because warm breath slips out from under the nose area where the mask doesn't fit right. Stop this problem by adding something flexible along the bridge. Pipe cleaners work great, or even those plastic twist ties from grocery bags. Just push them into the top edge of the mask and shape them snug against the nose once it's on. Getting the fit right matters too. Masks that sit lower on the face tend to work better since they let air flow down instead of escaping upwards. Place the mask so it rests beneath the cheekbones and make sure the bottom part covers all the way down to the chin. Medical tape might fix small gaps for now, though some folks find permanent stitching around the wire works best in the long run without needing sticky stuff.

Reducing Ear Strain Using Fabric Ties, Elastic Alternatives, and Pressure Distribution

Traditional elastic ear loops cause discomfort for 68% of prolonged mask wearers (Journal of Occupational Health, 2023). Replace thin elastics with solutions that redistribute pressure:

-

Fabric ties: Adjustable cotton straps distribute weight across the occipital bone

-

Headband hooks: Button attachments on headgear redirect pressure from ears

-

Wide straps: 1-inch knitted bands reduce pressure points by 40% versus standard elastics

For masks requiring loops, add silicone toggles or bead adjusters to customize tension. Wider ear loop mounts also prevent chafing by minimizing localized pressure.

Balancing Breathability, Filtration, and Thermal Comfort in DIY Face Masks

Optimizing breathability, filtration, and thermal comfort requires strategic layering. High-filtration materials often restrict airflow, causing heat buildup and discomfort during extended wear. Implement a three-tier approach:

-

Inner layer: Soft, moisture-wicking cotton for skin comfort

-

Middle layer: Non-woven polypropylene for particle capture (0.3-micron filtration)

-

Outer layer: Tightly woven hydrophobic fabric for splash resistance

The right balance between protection and comfort is key here. Too many layers just end up trapping heat, but too few will let particles slip through the filter. Good breathable designs are important because they reduce the effort needed when exhaling, which helps prevent air from escaping around the edges. When working in hot conditions, go for lighter weight materials and stick to no more than three layers total. This keeps things comfortable on the face without cutting corners on actual protection levels.

|

Design Factor

|

Optimal Range

|

Compromise Warning

|

|

Layers

|

2–3

|

>3 layers increase heat stress by 30%

|

|

Fabric Weight

|

80–100 g/m²

|

Heavier materials exceed 20 mmH₂O breathability limit

|

|

Fit Efficiency

|

>80% face contact

|

Gaps reduce filtration effectiveness by 50%+

|

Spunbond polypropylene offers five times better breathability than quilting cotton at comparable filtration levels. Regularly test seal integrity during activities to ensure sustained protection. Performance should be benchmarked against ASTM F3502 Level 1 standards (20% filtration at 0.3 microns), which represent the minimum functional threshold for community-use respirators.

Maintaining Hygiene, Odor Control, and Long-Term Performance of Reusable DIY Face Masks

Optimal Washing Frequency, Detergent Types, and Drying Methods for Cloth Masks

Wash masks daily after use to maintain cleanliness and prevent odors. Lianpu’s nonwoven masks are designed for long-term use: when washed correctly (gentle, unscented detergent at 60°C/140°F), they retain filtration efficiency for 50+ washes. Avoid bleach, as it degrades fibers—Lianpu’s materials lose only 10% of performance after 50 washes, compared to 12–15% for ordinary nonwovens. Air-dry naturally to preserve shape; laying flat on an airy surface (avoid direct sunlight) prevents shrinkage. Following these steps extends the mask’s lifespan to 6–8 months—Lianpu’s nonwovens resist fiber breakdown better than standard fabrics, thanks to their ISO 22716-certified manufacturing process.

FAQ Section

How can I ensure a proper fit for my DIY mask?

Bending aluminum wires along the top edge and creating contoured seams can effectively help a mask fit snugly around different nose shapes and facial curves.

What can I do if my mask keeps slipping?

Consider using adjustable toggles or fabric ties to secure the mask, and layered edges to maintain a firm grasp on facial curves.

How often should I wash my DIY mask?

Wash your mask daily using gentle, unscented soaps in warm water at 60 degrees Celsius or 140 Fahrenheit to effectively kill germs without damaging the material.

How can I prevent glasses fogging while wearing my mask?

Use flexible materials like pipe cleaners along the bridge of your mask to direct exhalation flow downward and ensure a tight fit under the cheekbones.

What fabrics are less likely to cause skin irritation?

Natural breathable fabrics, such as cotton or silk, allow air to circulate and reduce friction, minimizing skin irritation.

Hot News

Hot News